Energy Efficiency for Pumps

With Ecoclean's innovative energy efficiency solution, existing production plants are controlled so efficiently that consumption and costs are optimized by an average of 34%.

With Ecoclean average cost savings of 34% in the manufacturing industry.

A key factor in improving competitiveness is the reduction of unit costs. Our focus is on leveraging energy saving potentials within production, especially the often ignored but widespread auxiliary units.

Treatment systems such as wastewater, exhaust air, cooling, heating or cleaning systems usually operate 365 days a year and often completely uncontrolled. By means of Ecoclean-DFC, Ecoclean's Dynamic Flow Control, average cost savings of 34% have been achieved, quite often even more than 40%.

The leverage to save energy on the huge amount of existing industrial plants is much bigger and faster than simply waiting for an increasing population of energy-efficient new plants. Optimizations by Ecoclean usually pay off within two years due to the energy cost reductions.

Ecoclean-DFC

Ecoclean-DFC, Ecoclean's Dynamic Flow Control, is used primarily on auxiliary units.

These often operate 365 days a year and allow significant energy cost reductions.

A success story of energy cost reduction

- More than 30 reference projects

- Mean cost savings > 34%

- Cumulative energy savings > 80 GWh

- Amortization usually < 2 years

Ecoclean-DFC can be used without restriction wherever liquids or media of all kinds are pumped, i.e. in almost all branches of industry. Examples of application are central supply systems such as filter or coolant systems, cooling water circuits, i.e. cooling towers, heating circuits, systems in the paper, chemical or food industries, etc.

In addition to pump systems, supply systems of gaseous media, such as exhaust air systems, can also be optimized using Ecoclean-DFC. The principle is the same for blowers as for pumps.

Possible applications

- Central supply or disposal systems

- Filter or coolant (CCS) systems

- Cooling water circuits, i.e. cooling towers

- Heating circuits

- Exhaust air systems

- Systems in the paper, chemical or food industry

What makes Ecoclean-DFC special?

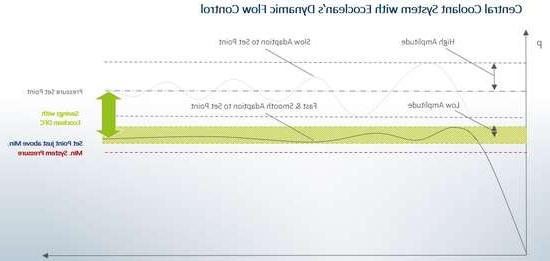

Ecoclean-DFC is designed for exactly these applications, i.e. for the control of supply systems with large but fluctuating media quantities. The inertial behavior of the media in large systems is an integral part of the logic of Ecoclean-DFC, as is the flexible response to large fluctuations in the demanded quantity.

The fast but smooth adjustment to the setpoint enables the reduction of the setpoint and allows the elimination of system reserves, as well as the elimination of bypass lines. Thus, energy can be saved and electricity costs reduced.

The required sensors for pressure and volume flow can be conveniently installed at a central point despite the high system complexity. This is an enormous advantage when retrofitting existing systems.

Function and features

- Control of large supply systems

- Takes inertia behavior into account

- Flexible response even to large fluctuations in demand

- Fast but smooth adjustment to the set point

- Conveniently retrofittable at a central location

- Significant reduction in energy costs

Easy retrofitting of Ecoclean-DFC

Ecoclean-DFC is primarily intended for retrofitting in existing systems in order to achieve maximum cost savings here. Accordingly, the required sensor technology can be conveniently integrated into the system at a central point, even if the overall system is highly complex.

Retrofitting possible on existing plants within a few days

The potential success of an integration of Ecoclean-DFC can be checked by one of our specialists prior to the retrofit. The savings expectation determined during this inspection will even be guaranteed by Ecoclean, a promise that is probably unique.

Ecoclean-DFC can be set up very quickly and without any major programming effort, and the reduction in consumption takes effect correspondingly quickly. The already short payback period thus begins immediately after commissioning.

Easy integration – Fast amortization

- Analysis of potential cost savings in advance by Ecoclean

- Guaranteed savings expectation

- Fast integration at a central point

- Short system downtime

- Immediate amortization of the investment

Further energy efficiency solutions with focus on cleaning systems

Reduction of consumption and energy costs in the manufacturing industry

Ecoclean is a specialist in the manufacture of cleaning equipment. In addition to Ecoclean-DFC, we offer our expertise for plant optimization of all types of cleaning systems. Especially in systems with sequential process steps, high energy saving potentials exist, also in the range of 34%.

An Ecoclean specialist will be happy to advise you on savings opportunities for your very own cleaning system.

Possibilities of consumption reduction at cleaning plants

- Analysis and consultation of the possible cost savings with Ecoclean

- Greatest potentials for plants with sequential process

- Integration of frequency converters

- Precise control via plant PLC

- Fast integration

Ecoclean-DFC - Our contribution to the energy transition and climate protection

Nominated for the Energy Efficiency Award 2022 of the German Energy Agency (DENA)

No other topic is currently as topical as measures to save energy. With innovative solutions for the pre-treatment machines in the production process of our customer Accuride, we were nominated for the Energy Efficiency Award 2022 in the category "From clever to digital! The bandwidth of energy efficiency".

In the production process of the Accuride pre-treatment machines, the various liquids circulate through 10 pumps in 8 zones. The pumps with up to 45 kW cause a significant part of the energy consumption in the production. All 8 zones were equipped with Ecoclean-DFC modules, sensors for pressure and flow detection were installed, and frequency converters were installed for each pump. The liquid circulation can now be controlled for each zone individually, thus significantly reducing the required energy consumption and eliminating previous losses.